CIPP PROJECT

Cure In Place Pipe

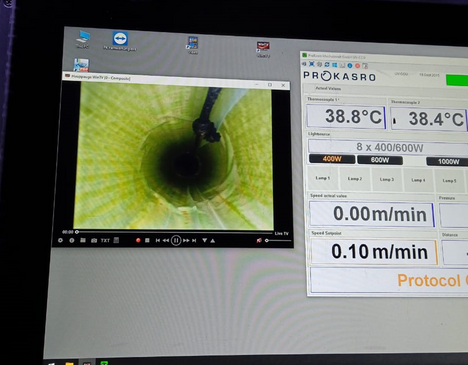

02 ProKASRO UV Operation

We employ state-of-the-art pressure testing equipment to ensure the integrity and reliability of the installed pipeline, exceeding industry safety standards.

State-of-Art Equipment

01 CCTV Pipeline Inspection

Utilizing the latest robotic pipeline inspection technology, we ensure accurate assessment and perfection of any issues, enabling targeted interventions.

03 ProKASRO Robot Cutting Operation

Our Cutting-edge cured-in-place-pipe lining technology allows for efficient and durable rehabilitation of pipelines, minimizing disruption and maximizing longetivity.

TRENCHLESS TECHNOLOGY

Revolutionizing Infrastructure

04 Infrastructure Projects

Discover the innovative benefits of trenchless technology, offering reduced disruptions, faster completion, and preservation of surface infrastructure.

Pre & Post Liner Inspection

05 CCTV Inspection

Pulling The Liner From Manhole "A" To Manhole "B"

06 Installation of Liner

07 Installation of Packer

To create a tight seal at both ends of the liner during the curing process

08 Reaching the 'Working Pressure'

Reaching the working pressure involves ensuring proper expansion, maintaining a secure seal, and preventing liner damage.

09 Insertion of UV Light Train

The UV light train is inserted into the liner to prepare it for curing, ensuring even distribution of UV light throughout the pipeline.

10 Curing the Liner

Curing the liner involves carefully controlling pressure, temperature, and time to ensure proper installation.

11 UV CCU Operation

Using the UV CCU (Control and Curing Unit), we monitor and control the UV curing process, guaranteeing a strong, fully hardened liner.

Robot Cutter Innovation

Contact us

PKM ENTERPRISE

No. 2, 1st Floor, Block A,

Q-Lap Complex, Simpang 88,

Kampong Kiulap, BE1518,

Negara Brunei Darussalam.

PROSAFE ENGINEERING COMPANY

Unit 6, 1st Floor, Rizqan Maisura Complex,

Kampong Tanjung Bunut, BF2920,

Negara Brunei Darussalam.

Call / Whatsapp us